How Modern Wallcoverings Empower Architects and Interior Designers

The architectural and design professions have witnessed a quiet revolution in wall surface technology over the past two decades. What began as simple paper printing has evolved into a sophisticated material science—delivering specification-grade performance, unlimited design flexibility, and installation efficiency that traditional methods could never match.

Digital wallcovering printing at 1200 DPI resolution, combined with Type II commercial-grade vinyl substrates in 40+ textures, gives architects and designers capabilities that fundamentally change how we approach wall surface specification. The question isn’t whether digital wallcoverings belong in your material palette—it’s understanding how to specify them effectively for different applications.

This transformation extends beyond aesthetics. Modern wallcoverings meet stringent building codes, achieve Class A fire ratings, satisfy low-VOC requirements, and deliver 10-15 year lifespans in high-traffic applications—all while offering complete design freedom impossible with traditional materials.

The Vinyl Revolution: From Paper to Performance

Traditional paper wallcoverings served architecture well for centuries, but they carried inherent limitations: susceptibility to moisture, limited durability in commercial applications, difficulty achieving consistent quality at scale, and restricted texture options.

The industry’s shift to vinyl wallcovering wasn’t purely aesthetic—it was driven by performance requirements in commercial architecture. Hotels needed corridor walls that could withstand luggage impact. Healthcare facilities required surfaces that could be cleaned repeatedly without degradation. Corporate offices demanded materials that maintained appearance through years of daily contact.

Vinyl construction solved these challenges while introducing new possibilities: embossed textures simulating organic materials, metallic finishes reflecting light dynamically, and surface treatments ranging from matte to high-gloss—all printable with full-color artwork at specification-grade resolution.

A New Generation of Wallpaper

Modern vinyl wallcoverings represent engineered material systems, not decorative afterthoughts. Type II commercial wallcovering specifications require materials to pass 12 rigorous physical tests: scrub resistance, tear strength, stain resistance, colorfastness, and flame spread characteristics under industry standards.

This performance level transforms how architects can specify wall surfaces. A printed vinyl wallcovering can replace materials costing 3-5x more while delivering comparable visual impact with superior maintenance characteristics and faster installation timelines.

The material palette has expanded dramatically. Where paper offered smooth or textured options, vinyl substrates now replicate leather grain, fabric weaves, plaster textures, metallic finishes, and experimental effects—each printable with custom artwork at production scale.

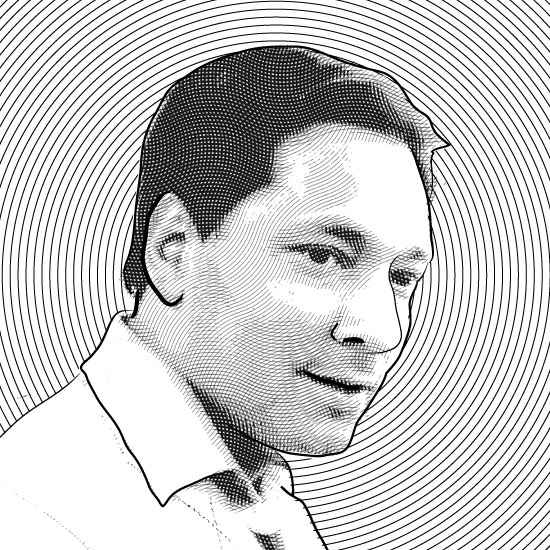

Leather Simulation

Genuine leather wall covering costs $35-75 per square foot installed, requires specialized maintenance, and offers limited color options. Leather-textured vinyl delivers comparable visual and tactile qualities at $8-12 per square foot while expanding color and pattern possibilities infinitely.

Materials like Cabretta feature embossed leather grain combined with matte vinyl surfaces—the texture reads as authentic leather under normal viewing distances, while the vinyl construction provides moisture resistance and scrubbability that genuine leather cannot match.

Strategic applications include hospitality lobbies, executive offices, restaurant interiors, and retail environments where leather aesthetics communicate luxury without the maintenance burden or cost structure of actual leather installation.

The specification advantage: identical material performance regardless of color or pattern choice. Unlike genuine leather where color variations affect cost and availability, printed vinyl maintains consistent pricing and lead times across unlimited color options.

Fabric Texture Alternatives

Textile wallcoverings bring warmth and acoustic benefits to interiors, but fabric construction introduces challenges: moisture sensitivity, staining susceptibility, limited durability in high-traffic applications, and maintenance complexity requiring specialized cleaning.

Fabric-textured vinyl replicates the visual and tactile qualities of woven materials while maintaining the performance characteristics commercial architecture demands. Surface embossing creates dimensional texture reading as actual fabric weave from normal viewing distances.

Materials range from tightly woven canvas effects to silk-screen finishes, suede simulation to knitted textures. Each accepts full-color printing, allowing pattern designs impossible with actual textile construction—gradients, photographic imagery, metallic accents, or multi-color graphics.

Performance advantage: Where textile wallcoverings require dry cleaning or specialized maintenance, fabric-textured vinyl tolerates standard commercial cleaning protocols. This distinction matters significantly in hospitality, healthcare, and corporate applications where maintenance efficiency directly impacts operational costs.

The cross-hatched texture shown above demonstrates dimensional complexity possible with modern embossing—creating surface depth that captures and reflects light dynamically while maintaining the cleanability vinyl construction provides.

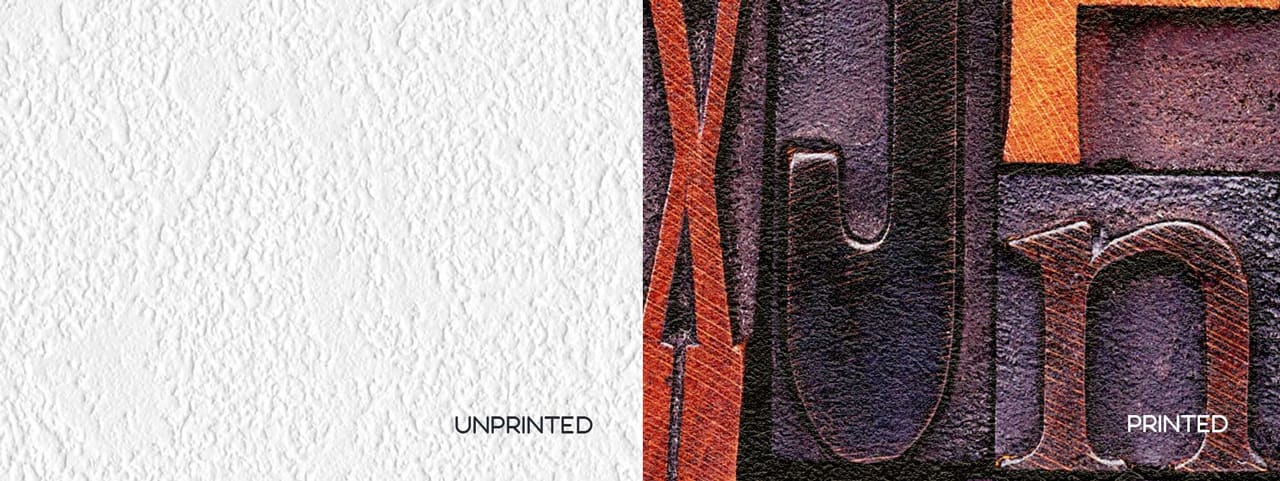

Traditional Paper Aesthetics

Period-appropriate design often requires authentic paper aesthetics—the subtle texture variations, matte finish, and organic feel that vinyl’s inherent characteristics might compromise. Modern materials address this through surface treatments replicating paper qualities while maintaining vinyl’s performance benefits.

Materials featuring paper-like texture provide the visual authenticity historic renovations or traditional interiors require without sacrificing commercial-grade durability. The surface reads as paper under normal viewing conditions—slightly irregular texture, matte finish, subtle color variation—while the underlying vinyl construction delivers moisture resistance and longevity paper cannot match.

Strategic applications include historic preservation projects requiring period accuracy, traditional residential interiors, hospitality spaces emphasizing classic aesthetics, and any environment where paper authenticity supports design narrative.

This category demonstrates how material engineering can balance aesthetic requirements with performance needs—delivering visual characteristics that communicate “traditional” while meeting contemporary building standards for durability and maintenance.

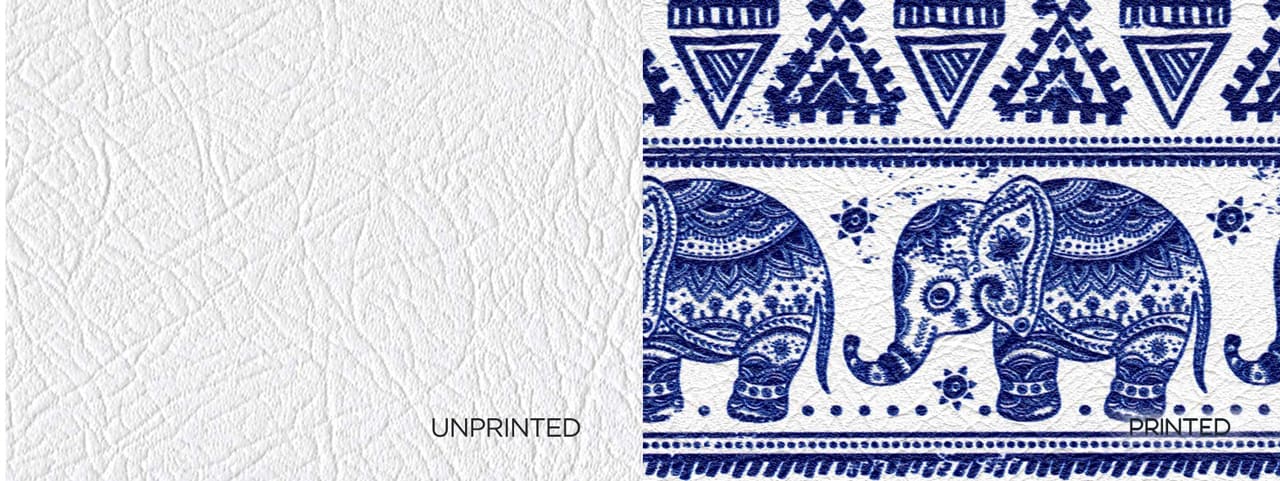

Textured Grit Finishes

Surface texture affects how artwork reads under lighting—smooth surfaces create different visual effects than textured ones. Fine-grit textures add dimensional depth to printed graphics, creating subtle shadow patterns that change with lighting angles.

Sandpaper-textured materials range from fine to coarse grit, each creating different visual effects. Fine grit adds subtle texture without overwhelming printed detail. Medium grit creates more pronounced surface variation. Coarse textures make bold statements while potentially sacrificing some print detail visibility.

The material shown above demonstrates how grit texture interacts with printed artwork—creating visual depth through micro-shadows while maintaining overall image clarity. This technique works particularly well for abstract patterns, geometric designs, or artwork where slight texture variation enhances rather than compromises the visual concept.

Specification consideration: Grit textures affect cleaning protocols. Fine-grit surfaces tolerate standard commercial cleaning. Coarser textures may require more attention during maintenance planning—a factor to consider when specifying for high-traffic or institutional applications.

Plaster Surface Effects

Hand-plastered walls communicate craft and texture impossible to achieve with smooth surfaces. But actual plaster installation requires skilled labor, extended timelines, and costs that strain most project budgets. Plaster-textured vinyl offers an alternative—replicating the visual and tactile qualities of hand-troweled surfaces while maintaining vinyl’s performance characteristics.

The embossed texture creates irregular surface variations reading as authentic plaster work from normal viewing distances. When printed with appropriate colors—whites, creams, earth tones—the effect becomes convincing enough for applications where genuine plaster would traditionally be specified.

Strategic applications include restaurants and hospitality seeking rustic aesthetics, residential projects emphasizing craft details, retail environments communicating artisanal qualities, and any space where plaster texture supports design narrative without requiring actual plaster installation.

Installation advantage: Unlike genuine plaster requiring weeks of application and curing, plaster-textured vinyl installs in days using standard wallcovering techniques. This timeline compression matters significantly in tenant improvement projects or renovations where extended closure costs exceed budget tolerance.

Metallic & Reflective Finishes

Metallic wallcoverings introduce dynamic lighting effects impossible with matte or semi-gloss finishes. Reflective surfaces capture and redirect light, creating shimmer and depth that changes with viewer position and lighting angles.

The spectrum ranges from subtle pearlescent sheens to high-gloss metallic finishes, each creating different visual effects. Subtle metallics add dimensional depth without dominating. Full-metallic finishes make bold statements through dramatic light reflection.

These materials accept full-color printing—allowing designers to combine metallic properties with custom artwork, patterns, or graphics. The result: surfaces that shift appearance based on lighting conditions and viewing angles, creating dynamic visual experiences impossible with static finishes.

Technical consideration: Metallic finishes reflect light predictably but dramatically. Lighting design must account for these reflective properties—what works beautifully under diffused lighting might create problematic glare under direct illumination. Press proofs reviewed under actual lighting conditions prevent expensive surprises.

Strategic applications include luxury retail environments, hospitality lobbies, high-end residential spaces, corporate feature walls, and any application where dynamic lighting effects enhance design impact.

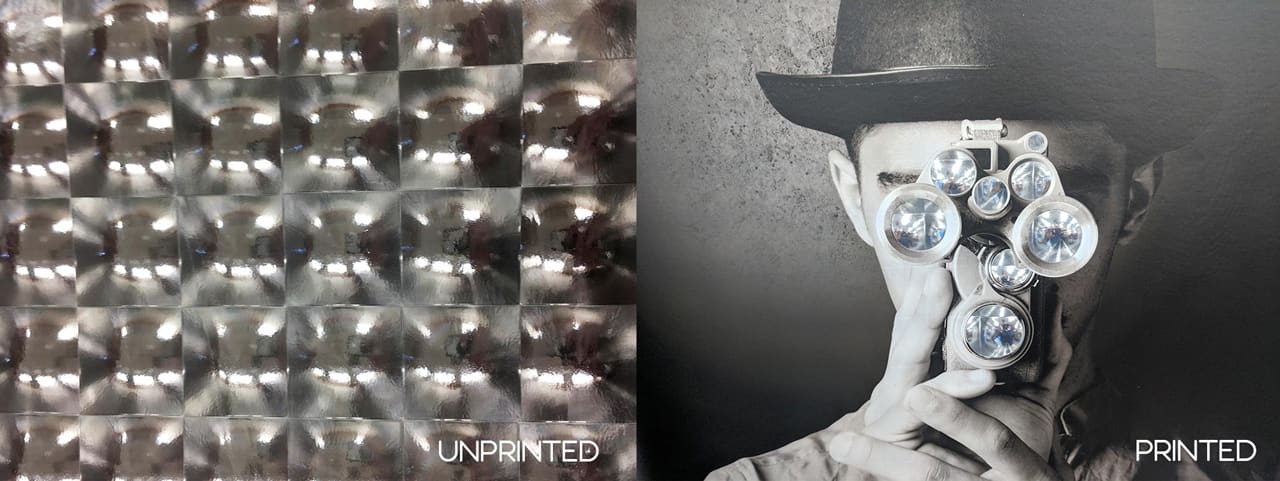

Experimental Surface Technologies

Some material technologies resist simple categorization—combining multiple surface treatments or introducing optical effects that change appearance based on viewing angles and lighting conditions.

Fractal lens patterns create three-dimensional optical effects through microscopic surface geometry. Metallic cross-hatched textures combine reflective properties with dimensional surface variation. Stippled surfaces with metallic accents create shimmer effects through both texture and finish.

These materials push boundaries of what wall surfaces can achieve visually. They’re not appropriate for every application—their bold visual effects can overwhelm rather than complement design concepts if misapplied. But in applications where dramatic wall surfaces support design narrative, they offer capabilities standard materials cannot match.

Specification approach: These materials work best as accent elements rather than entire room installations. Feature walls, elevator lobbies, reception areas, or other spaces where dramatic impact serves design goals benefit from experimental surface technologies.

The material shown above demonstrates how optical effects create visual complexity—the surface appears to shift and shimmer as lighting or viewing angle changes, creating dynamic visual interest impossible with static finishes.

Beyond Walls: Floors and Ceilings

The term “wallpaper” undersells capability—modern vinyl wallcoverings install successfully on floors, ceilings, and curved surfaces. Material engineering addresses each application’s specific requirements: slip resistance for floors, adhesive systems for overhead installation, flexibility for curved applications.

Floor applications require slip-resistant certification under ANSI A137.1 standards. Materials meeting these requirements can replace traditional flooring in temporary installations, create decorative floor patterns, or provide wayfinding graphics integrated into floor surfaces.

Ceiling applications introduce different challenges—gravity affects adhesive performance, installation requires overhead working positions, and seam visibility increases when surfaces can be viewed from below. Material selection and installation technique both matter significantly for successful ceiling installations.

Curved surface applications require material flexibility allowing conformance to compound curves without wrinkling or lifting. Not all materials suit curved applications equally—some maintain flexibility while others resist conforming to tight radii.

This expanded capability transforms how designers can approach spatial graphics—treating entire room volumes as printable surfaces rather than limiting custom graphics to vertical walls.

Building Code Compliance & Technical Performance

Architects face daily responsibility for building code compliance and material performance. Modern wallcoverings address these concerns through third-party testing and certification documentation.

Technical specifications cover: - Fire safety: ASTM E-84 Class A ratings with flame spread 0-25 - Air quality: Low-VOC emissions meeting California 01350 standards - Durability: Type II performance under WA-101 testing protocols - Environmental: NSF/ANSI 342 sustainability standards

This documentation isn’t marketing material—it’s third-party laboratory certification providing the verification architects need for specification and submittal processes. Fire marshals, building inspectors, and insurance underwriters accept these certifications as meeting code requirements.

Practical significance: Architects can specify custom-printed wallcoverings with confidence they’ll pass building department review. Contractors can install without concerns about inspection failures. Property owners can insure without special riders or exceptions.

The transformation from decorative afterthought to specification-grade material system changes how wallcoverings integrate into architectural practice—moving from interior designer discretion to architect-specified building system.

Material Selection Strategy

With 40+ material options, specification becomes strategic rather than arbitrary. The decision framework considers application requirements, aesthetic goals, budget parameters, and timeline constraints.

High-traffic commercial applications: Type II materials with proven durability under WA-101 testing. Matte or low-gloss finishes minimize visible wear patterns.

Luxury hospitality or residential: Materials communicating appropriate aesthetics—leather textures, fabric simulations, metallic finishes, or specialty surfaces supporting design narrative.

Budget-conscious projects: Standard materials delivering required performance at lowest cost. Material cost variations can reach 2-3x between basic and specialty options.

Timeline-sensitive projects: Materials readily available from inventory versus custom orders requiring lead time. Standard materials ship within days; specialty items may require weeks.

Historic renovation or adaptive reuse: Materials replicating period-appropriate aesthetics while meeting contemporary building standards.

The specification process benefits from physical samples reviewed in actual lighting conditions. What appears perfect under office fluorescents may read differently under the warm lighting hospitality projects favor, or the high-intensity illumination retail requires.

The Design Freedom Advantage

Traditional wallcovering manufacturing required minimum order quantities measured in thousands of yards—economical only for mass-market patterns sold through retail channels. Custom patterns meant prohibitive tooling costs and long production timelines.

Digital printing eliminates these constraints entirely. Single-room quantities become economically viable. Custom artwork prints at the same cost as stock patterns. Design iterations happen digitally without tooling changes. Production timelines compress from months to days.

This transformation changes how designers approach wall surfaces—from selecting among available patterns to creating custom designs specifically for individual projects. The wall surface becomes a design element as controllable as any other specification rather than a constraint limiting creative options.

Project management matters significantly at this scale. Coordination services ensure artwork files meet technical requirements, material selections suit application needs, panel layouts optimize installation efficiency, and delivery timing aligns with construction schedules.

For multi-location projects—hotel chains, restaurant franchises, corporate campus installations—consistency across sites becomes critical. Digital printing delivers identical results regardless of order size or timing, ensuring brand standards maintain across all locations.

The Professional Workflow

Successful wallcovering specification requires coordination between design intent, technical requirements, and installation reality. The workflow typically progresses through distinct phases:

Concept Development: Designers develop visual concepts, select preliminary materials, establish color palettes and pattern scales.

Technical Review: Files evaluated for resolution, color mode, pattern registration, and production feasibility. Issues identified and resolved before production.

Material Sampling: Press proofs printed on actual production materials using identical process for final production. Physical samples reviewed under actual lighting conditions.

Production: Full-scale printing following sample approval. Quality control throughout production ensures consistency with approved samples.

Installation Coordination: Detailed schematics showing panel layout, seam locations, and installation sequence. Coordination with contractors ensuring proper surface preparation and installation technique.

This structured approach prevents the costly mistakes that occur when any phase gets compressed or eliminated. The press proof phase particularly matters—discovering color or scale issues after full production wastes both time and budget.

Material Science Serving Design Intent

The evolution from paper printing to engineered vinyl systems represents more than technological progress—it reflects architecture’s ongoing demand for materials delivering both aesthetic impact and long-term performance.

Modern wallcoverings serve design intent while meeting building standards, maintain appearance through years of commercial use, install efficiently within project timelines, and provide maintenance characteristics property owners require.

At Fine Print NYC, we’ve spent two decades working with architects and designers navigating material selection, technical specification, and project coordination. We understand that wallcovering specification sits at the intersection of creative vision and practical constraints.

Begin your project: Call (212) 619-5446 and ask for Joseph, or email directly with project details. Include design concepts, application requirements, performance specifications, and timeline constraints.

We’ll provide material recommendations, technical documentation, physical samples for review, and coordination support ensuring your wallcovering specifications deliver both design impact and specification-grade performance.

The architectural palette has expanded. Wall surfaces are no longer constraints but opportunities—printable canvases accepting unlimited design possibilities while maintaining the performance characteristics commercial architecture demands.